Manufacturing

Manufacturing

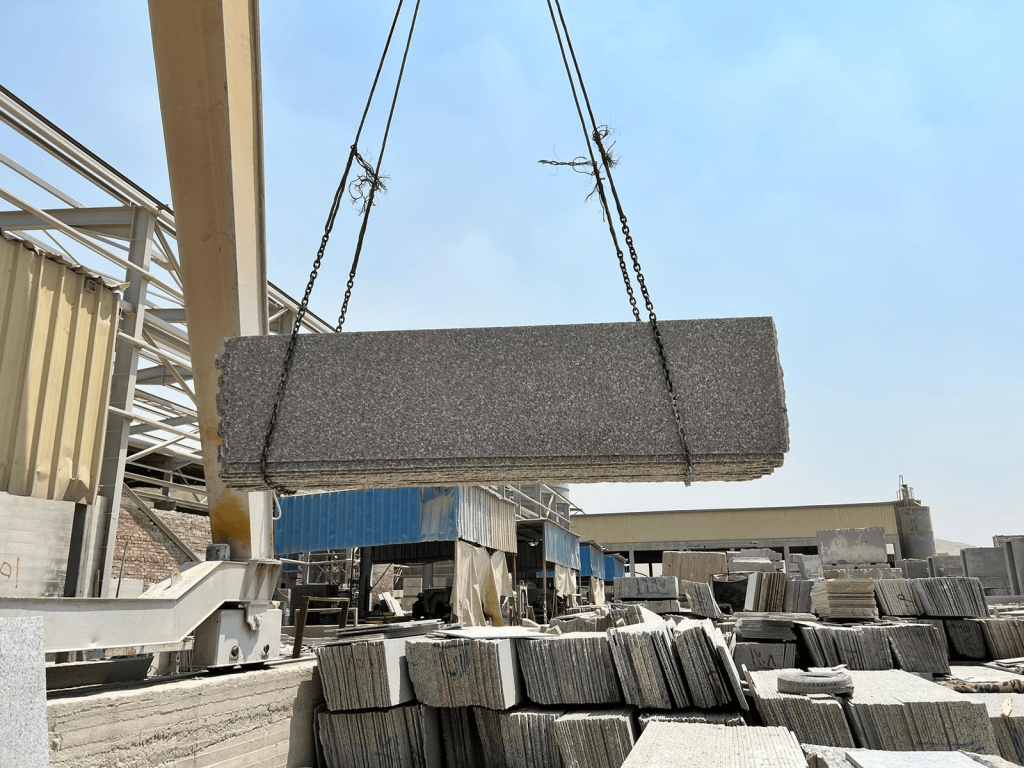

Marble and granite manufacturing involves extracting blocks from quarries, cutting them into slabs, and then grinding and polishing them for a smooth finish. The slabs are then finished with edge treatments and sealants. Finally, they undergo quality control before being packaged and shipped.

Our Manufacturing Process

Extraction: Large blocks of marble and granite are extracted from quarries using wire saws or explosives. This process is carefully managed to ensure the blocks are removed with minimal damage.

Block Dressing: Once extracted, the blocks are trimmed and squared to prepare them for further processing. This step ensures the blocks are in the proper shape for cutting.

Cutting: The dressed blocks are sliced into slabs. Marble slabs are generally thinner, while granite slabs are thicker due to the hardness of the material.

Grinding and Polishing: The slabs are ground to smooth their surfaces, followed by polishing to achieve a high-gloss finish. This step enhances the stone’s appearance and texture.

Finishing: Edges of the slabs are finished to create the desired profile, and a sealant may be applied to protect the stone from stains and moisture.

Quality Control and Shipping: The final slabs undergo thorough inspection for defects before being carefully packaged and shipped to their destinations.